WASHINGTON — Metro maintenance platforms for the system’s new trains sat unused at the New Carrollton Rail Yard because they do not meet safety standards, new Federal Transit Administration inspection reports show.

An inspection on June 22 found that the elevated platforms on two maintenance tracks had been completed as designed but after construction, Metro ordered workers not to use them because:

- The gap between the platform and the car is dangerously wide, posing a risk that workers could fall between the platform and the car.

- The grating used for maintenance workers to walk on has gaps that are wide enough to allow dropped tools to fall through, potentially hitting someone walking below.

- There is no safety railing.

The elevated platforms are needed for maintenance of the 7000 Series cars because their design includes key pieces mounted on top of each rail car pair.

Metro has been doing maintenance on the cars at other rail yards and had corrected the problems for construction of a safe maintenance platform on a third track in the New Carrollton facility that had not yet been completed at the time of the inspection.

An internal Metro report raised concerns this summer about whether the system’s technicians have enough training and space available to work on the new trains.

The just-released FTA report notes Metro recently updated several of its rail car maintenance manuals, including for the 7000 Series cars.

Other rail yard issues

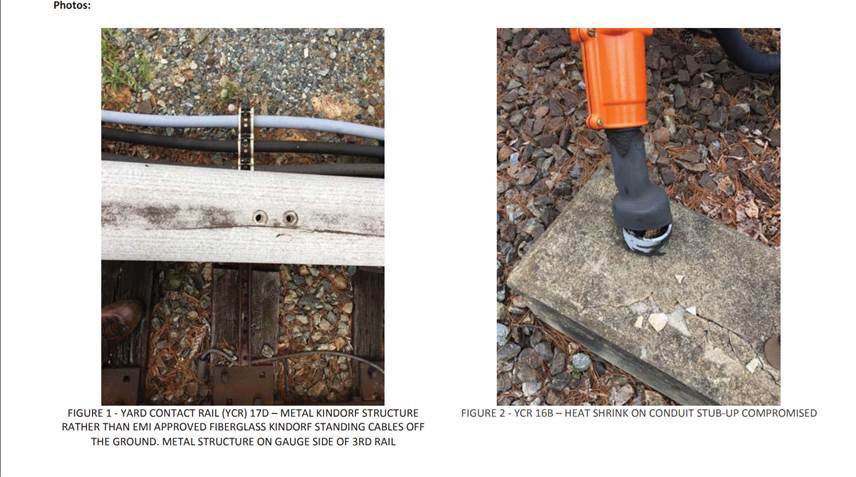

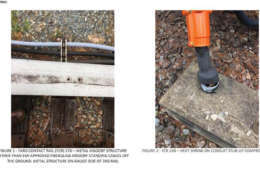

At the New Carrollton, Branch Avenue and Alexandria rail yards, federal inspectors found several track and power cable issues.

In the Branch Avenue yard, there were at least two locations where the rails were sliding left or right due to loose connections to the rail ties.

In the Alexandria yard, “numerous” cross ties were also found to not be properly holding the tracks in place. The FTA had already warned Metro about the Alexandria issue, the inspector noted.

In shops, Metro has implemented new precautions against derailment after a rail car derailed in April because workers forgot to remove a block meant to keep it in place during repairs.

Metro has made the blocks brighter and added a high visibility flag to make removing the wheel chocks harder to forget. As of late June, Metro was still waiting on more of the new, brighter chocks and flags so that they could be rolled out in all maintenance facilities.

At the Shady Grove facility, an inspector raised concerns on back-to-back days in July because the power for the system that lifts the car into the air for repairs was left on, despite explicit instructions to power the system off except when a car is being raised or lowered.

A supervisor promised to take care of the issue each time.

Other basic maintenance and repair steps reviewed by the FTA got the thumbs up, including regular checks on doors, brakes and other features of several different generations of rail cars and a contractor’s inspection of a newly delivered pair of 7000 Series rail cars.