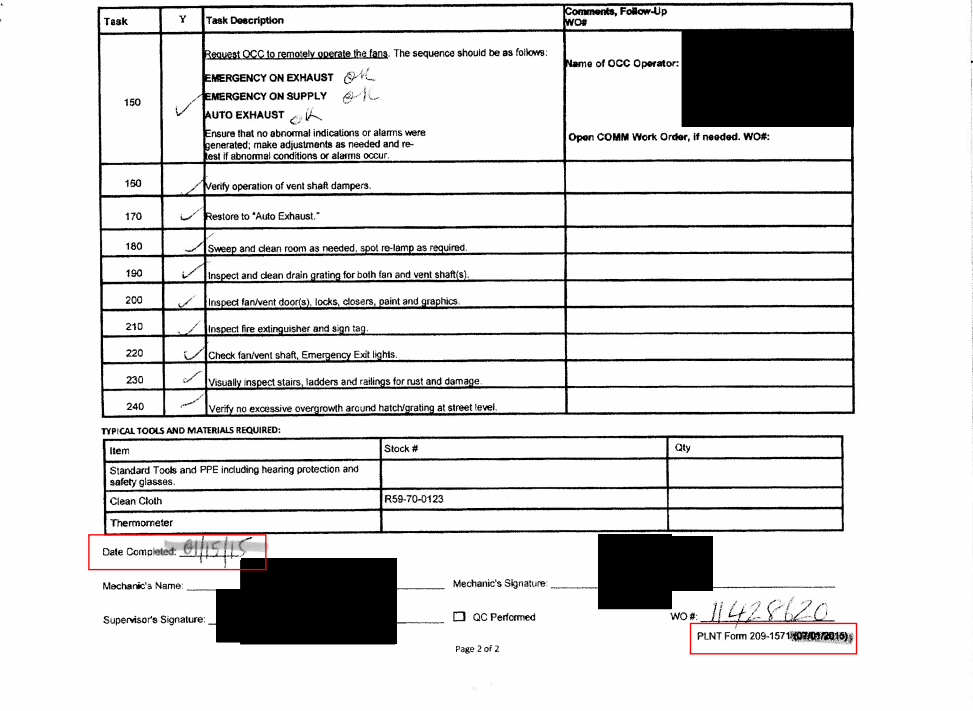

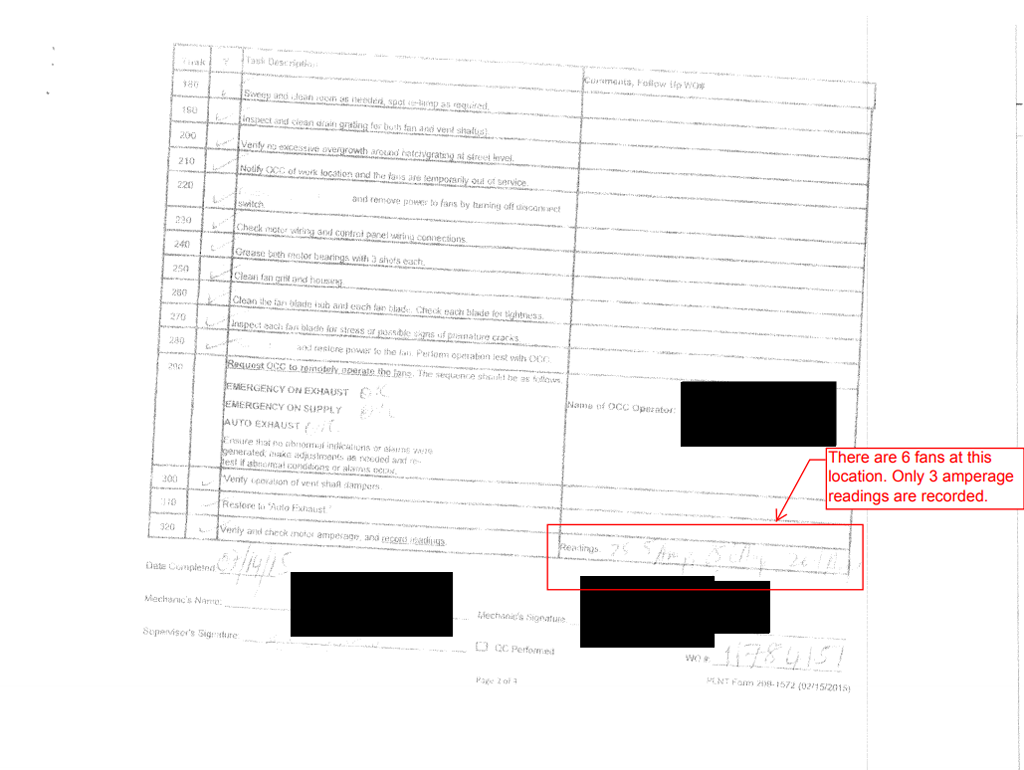

WASHINGTON — An internal Metro review found that some crucial maintenance records for tunnel ventilation fans were possibly falsified, prompting a call for an investigation into the transit agency’s maintenance documentation practices.

Metro’s office of Quality Assurance, Internal Compliance & Oversight discovered that four reports between 2014 and 2016 predated the creation of the form that was used to document the purported maintenance.

“QICO identified several instances of maintenance record modification,” said the internal report dated June 9.

The internal review comes after Metro has fired maintenance staff for falsifying other types of maintenance records.

The review also found that other records indicate that some preventive maintenance may have been skipped. And some reports had illegible comments from inspectors or lacked comments detailing the results of the tests and inspections.

Last year, Metro fired or disciplined nearly half of its separate track inspection department over what it said were falsified track inspection reports.

Those fired inspectors have challenged the firings on a number of grounds, including claims that they were simply doing what Metro supervisors had instructed them to do.

A fan mechanic, who was fired for similar reasons after the investigation into Carol Glover’s death outside L’Enfant Plaza, won an arbitration case after he revealed potentially falsified maintenance work.

In April, a judge ordered Metro to reinstate the worker.

Federal investigators found that the fans were not used correctly leaving Glover and other riders trapped in the acrid electrical smoke for more than 30 minutes before they were rescued from the Yellow Line train.

Other fan inspection issues

The overall review found that the fans and dampers tested at 12 selected sites across the subway system generally worked, areas the fan maintenance crews were responsible for were clean, and preventive maintenance was scheduled.

However, the review found that other Metro departments had left equipment and debris blocking fan shafts or emergency exits; supervisors were not focused on quality control; maintenance documents were not up to date or complete; and a lack of coordination among departments.

Inspectors also found ventilation fans that were not properly stabilized because mechanics said they had run out of funding for higher-end pieces, so they used cheaper isolators instead.

“These 2 fans are now more susceptible to increased vibration,” the report found.

In other spots, emergency exit stairs were rusting and multiple drains were clogged or blocked. Some fan shafts also had deteriorating concrete that should be addressed before they become a serious problem.

The internal oversight group found that those issues were not shared with departments that could make the repairs.

Metro is also behind schedule on crafting detailed, written tunnel ventilation procedures that would be used in the event of a smoke event or a fire and would be specific to the location of the incident and location of a train.

The Federal Transit Administration had rejected Metro’s initial attempts at a fire and life safety maintenance procedure that would delineate responsibilities for things like tunnel fan inspections and repairs, and has asked that it be combined with a ventilation system testing process.