This video is no longer available.

Twisting a twist tie or peeling off a sticker is a challenge that can stop some people with disabilities from earning a living they can be proud of. But a group of high school students in Montgomery County, Maryland, is trying to solve that problem for a Northern Virginia ice cream shop that employs people with disabilities.

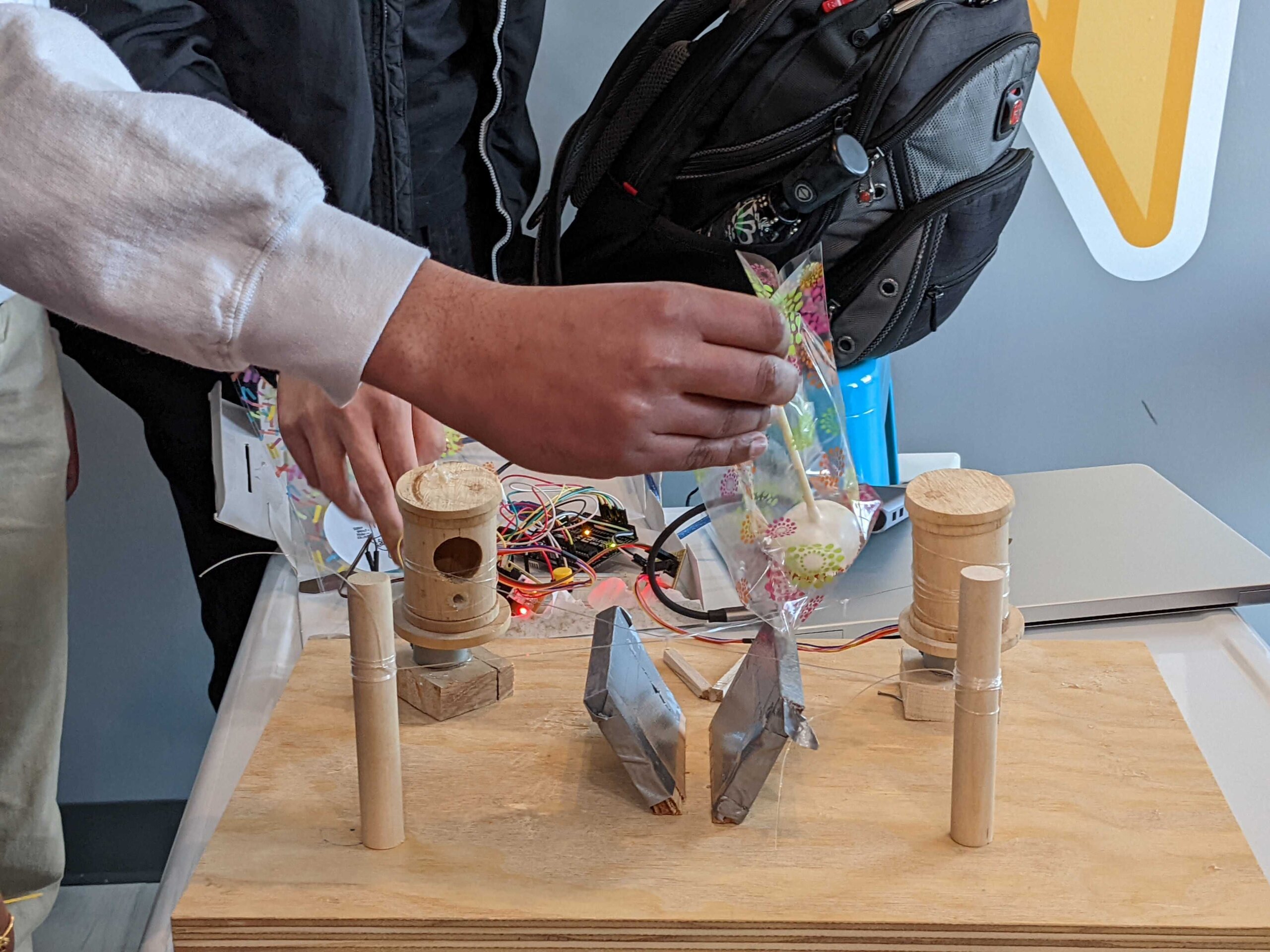

Saatvik Soma, 16, James Xu, 17, and Sanjana Konka, 17, are part of the Science, Math and Computer Science Program at Poolesville High School. The 11th-graders are called Team SKX, and they’re making a machine that will help the employees at Jake’s Ice Cream put a twist tie on a cake pop bag and other kinds of packages.

After reaching out to the shop’s owner, Soma, Xu and Konka observed the employees. One of the things they saw was the complexity of putting a twist tie.

“For us, it may seem really simple, just holding a bag and scrunching it and just putting a twist tie around it,” Soma said. But for someone with fine-motor issues or even one hand, it could be hard to hold a bag, scrunch it and twist all at the same time.

The team brainstormed and came up with many ideas. Using computer-aided design, or CAD, software, they started with some models; from there, they were able to start building. But it took several tries.

“We came up with a lot of ideas, and we had to physically build and prototype all of them out of wood to quickly test all the ideas,” Xu said. “And the complexity of the problem just meant that the nature of creating a solution that would actually solve it fully is just very, very difficult.”

They had to scrap many ideas and brainstorm new ones for weeks, and even when they thought they had created something they felt confident about, testing revealed problems they did not see at first.

“Which meant we had to just scrap it, and come up with a new idea and make it again and repeat,” Xu said.

Frustrating but rewarding

Konka said it was kind of frustrating to have to scrap things they had put in a lot of work to create. Not only that, but they were under a time crunch: The students were entering their design in the SourceAmerica IDEATE Engineering Competition, which challenges high school and college engineering students nationwide to create assistive technology that “increases workplace success for people with disabilities.”

Vienna, Virginia-based SourceAmerica advocates for hiring and expanding employment for people with disabilities.

Team SKX has a legacy to live up to. Last year, a Poolesville High School team took second place in the high school competition. Over the last decade, the school has placed among the top several times, the team’s supervisor Kevin Lee said.

Although it was sometimes frustrating to start over, it was also kind of rewarding, Soma said. “Because we know that once we test a design, we don’t have to go back to it, because we know that ‘Oh, it doesn’t work,’ so we can move on from there. We were able to cross different ideas off our checklist of what to design. And so we were able to narrow down more and more to what actually works.”

Scrunching a bag

The team broke down the process of tying a twist tie into multiple steps, and one idea they came up with was a handmade spool mechanism to scrunch the bag together. It did the job and it was usable, but they wanted to make it more efficient.

Xu said they were exploring “different knots to tie on a string,” hoping to apply some of the principles to the scrunching of the bag. That included exploring rope theory, which Xu said “is pretty odd to think about,” but had a lot of potential.

They tested out a Honda knot — which allows one part of the string to move back and forth — but it was too hard to undo.

They were stumped until Xu suggested a modification in the knot, which Soma called “kind of a eureka moment.”

The prototype they presented to the staff and some of the employees’ parents almost two weeks ago was the fourth one they built. It was the first time they were showing it, and members of Team SKX were taking notes on how to improve the design even more.

Some suggestions from parents and staff included adding colors to some of the parts of the machine, because some of the staff also have issues with vision; many were former patients of owner Robin Rinearson, who is a retired optometrist. Other suggestions included making the strings thicker, especially for those with fine-motor issues, and adding a camera lens, which Xu said they started 3D modeling plans for.

In addition to the suggestions, they are also trying to fix the spools in the prototype, and they are going to explore automating the tying of the twist tie.

“We did have plans for doing that earlier, but we kind of scrapped it because it wasn’t working out for us. But now we want to revisit those plans and make them better,” Soma said.

For now, they will submit the prototype for the contest, the deadline of which was last Friday, Feb. 18. But Soma said they will keep working on a final product for Jake’s Ice Cream.

A mindset of inclusion

The outcomes of the IDEATE Engineering Competition over the past years have had very local applications, said Shane Kanady, SourceAmerica’s vice president for workforce development. That’s because the students have to partner with local groups to create solutions.

“We really focus on implementation and positive impact,” said Charissa Garcia, SourceAmerica’s senior productivity engineer. “We really look at teams who cocreate with their subject matter expert teams, who take feedback from that person and change their design in order for it to be more suitable for the environment. And those that showed the greatest change.”

And that impact could be an increase in productivity or even a decrease in anxiety and waste.

The competition aims to pair strong technical skills with very strong social skills, Garcia said, because learning to design with somebody is a very specific skill set.

“A lot of people who design don’t get to have that experience, particularly for designers who are so young. And so being able to accept that your experience is not the only experience and that someone else’s lived experience has an incredible amount of value puts you in a position to design in a way that is going to be so much more effective in the end,” Garcia said.

Konka said she learned to be more patient in doing the project and also to look at things in a different perspective, “because there were a lot of things that we didn’t exactly see or realize.”

Soma said that he learned how determined the employees were.

“They want to learn and they want to help their community and help better themselves. And so it’s really inspiring to see just how determined they are to just, like, work,” Soma said.

Kanady hopes that students come away with a mindset of inclusion.

“Just the simple result that comes from having a program like this is a younger generation of engineers are predisposed to include persons with disabilities in their thought process. That’s a huge, huge benefit,” Kanady said.

The finals event for IDEATE will be on April 13. Each school associated with a finalist team will get $1,000 and then each individual team member also receives a gift card.

Garcia sees another reward for the students.

“Watching them go from ‘I’m a little nervous about working with people that are different from me’ to, ‘This person is my friend. And of course they can do this job, and they just need the right tool set,’ is an amazing educational arc that is so difficult to teach in a classroom without hands-on experience,” she said.