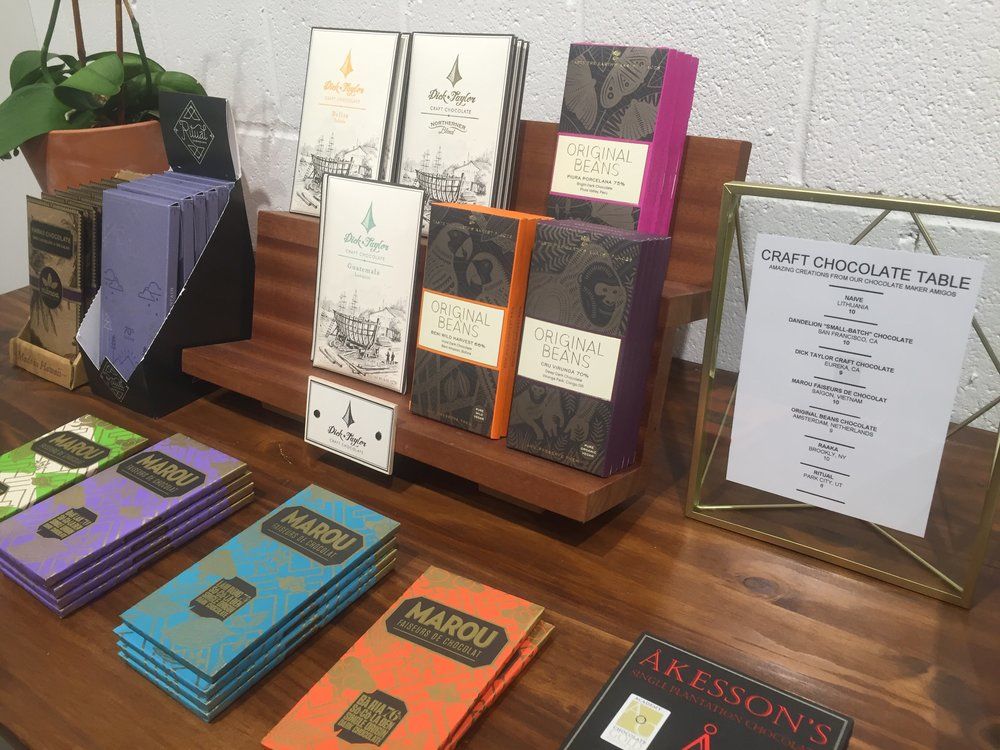

WASHINGTON — Think chocolate for Valentine’s Day is cheesy or boring? Think again.

D.C.-based artisan chocolate company Harper Macaw is anything but.

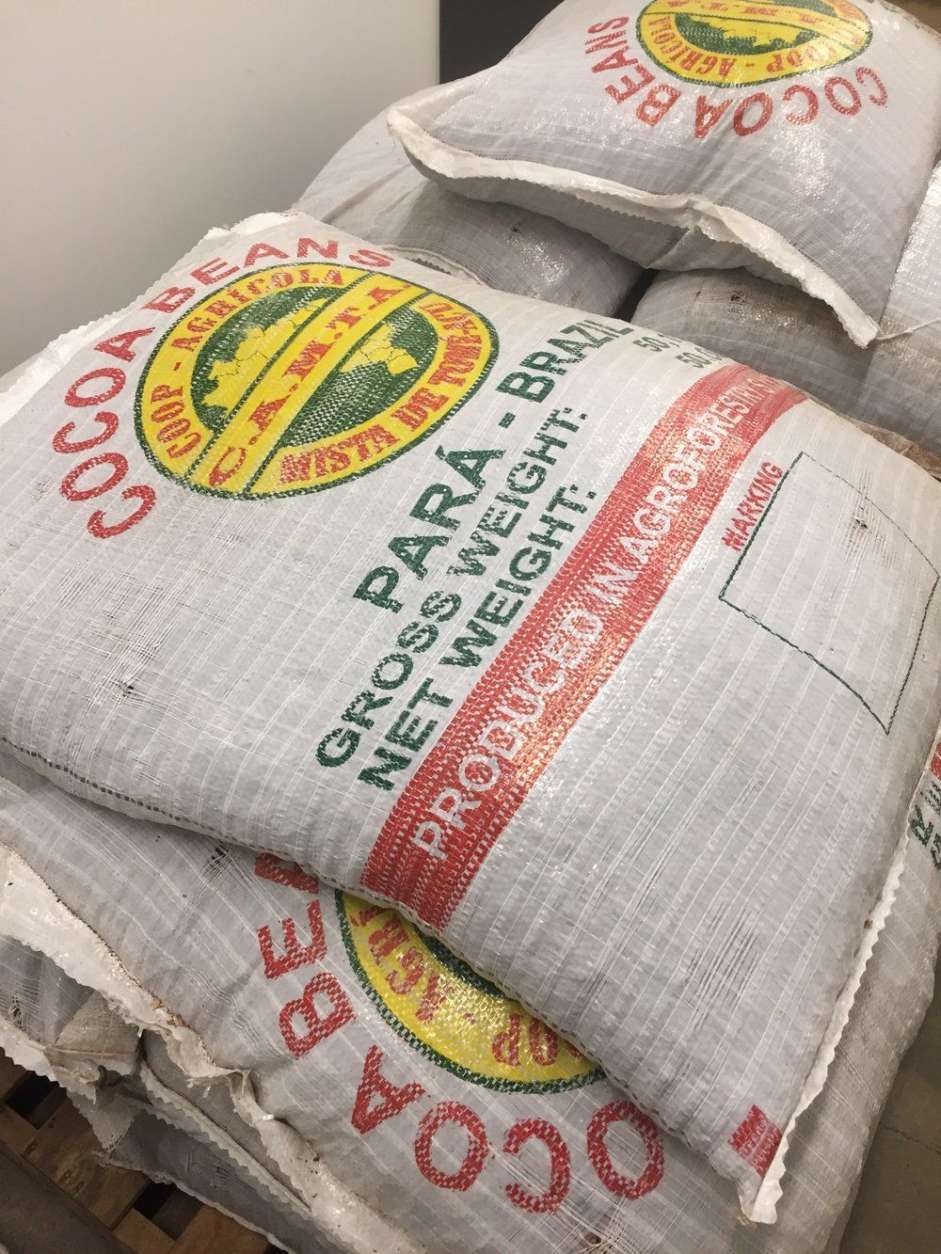

Owners Colin and Sarah Hartman’s brand is one that’s built around rainforest conservation — they even named their company after two endangered bird species. The harpy eagle and the hyacinth macaw are native to the region of Brazil, from which Harper Macaw’s cocoa beans are sourced.

Business partners by day, doting parents by night, the husband-and-wife duo come from interesting backgrounds. She is from a long line of Brazilian entrepreneurs; he is a former U.S. Marine. Together, they’ve spent more years traveling than not, but what grounded them in the end was Sarah’s passion for craft chocolate and sustainability. Coupled with Colin’s MBA and the desire to create something totally unique, Harper Macaw was born.

They’ll be the first to tell you: Not all chocolate is created equal. Colin said the key to the company’s success lies in their ability to control the chain, by bringing all aspects of the business in-house — from the sourcing to the manufacturing, from the marketing to the distribution.

Colin and Sarah’s artisan chocolate factory, located on the outskirts of Northeast D.C., is unassuming from the outside: It’s tucked discreetly between a Good Year Tire on the left and a post office on the right. But it’s what’s on the inside that truly matters.

Walking inside the factory is somewhat reminiscent of the Brazilian oasis the couple seeks to restore through their chocolate production. And back behind the retail front lies the key to each artfully designed chocolate bar: the machines and hands that craft them.

Colin revealed Harper Macaw’s chocolate-making steps and what it takes to get to the final product.

Sorting the cocoa beans: The ultimate goal is to combine the beans that fit the same size profile. If they are too small, they’ll burn in the roaster, and if they’re too big, they won’t have fermented properly, which contributes to the flavor of the chocolate.

Light roasting: Similar to the difference between that of a light-roast versus dark-roast coffee, the Harper Macaw light-roasting process is robust enough to bring out the complexity in the flavor of the high-quality cocoa beans they source and retain the slightly more acidic, earthy, fruitier notes. About 132 pounds of cocoa beans are poured into the drum roaster for one batch, rotating slowly, roasting the cocoa over a period of an hour to an hour and a half at a temperature of about 300 degrees Fahrenheit. This burns off acidity before dropping down to a much lower temperature for the remainder of the roasting process.

Sending the roasted beans through the winnower: The winnower machine shatters the roasted cocoa bean and vacuums out the shell. Calibration must be precise in order to avoid unnecessary product waste that could either suck up expensive essential ingredients like cocoa nibs, or if the vacuum is too weak, leave remaining shells. The delicate balance of the two creates the perfect byproduct.

Grinding the cocoa nibs: This process chops up the roasted beans into a liquefied paste. Then, cane sugar is added. If you’ve ever wondered what the percentage on the outside of your dark chocolate bar stands for, it’s the ratio of chocolate nibs to sugar.

A 75-percent dark chocolate bar is 75 percent dark chocolate cocoa nibs and 25 percent sugar. But, Colin said, always be sure to check the label for a list of ingredients. Be aware of what other ingredients may be included in that 25-percent non-cocoa category, such as soy.

And if the ingredient “chocolate” is also listed, that means the company is buying finished chocolate from a chocolate manufacturer and melting it down; they’re basically chocolatiers adding more ingredients and creating something else.

But if the ingredient is cocoa beans or cacao, then they actually started with the cocoa beans and were part of the chocolate-making process, from beginning to end. The chocolate maker will have more influence on the flavor, which often corresponds with the price tag, since more labor and equipment costs are involved in controlling the process.

After cocoa nibs, cane sugar and dehydrated milk — in the case of milk chocolate — are ground together, they pass into a buffer where the chocolate “liquor” is pumped into a roll mill.

Refining: A particle refiner — in this case, a roll mill — creates a chocolate consistency equivalent to that of European-style chocolate manufacturers: velvety, smooth and creamy. The chocolate then falls into the conche.

Conching: A large, enclosed, trough-like container heats the chocolate, and mixing arms churn the chocolate in a process called “conching.” Here, the cocoa solids, cocoa butter (fat of the cocoa bean), sugar and milk (in the case of milk chocolate) particles are aggressively combined together and rounded-out to finalize texture. More importantly, the chocolate is aerated and volatile flavor compounds and acidity are released from the chocolate in order to make it taste mellower and less acidic.

Chocolate can start off overly flavorful and powerful, so this process is analogous to actively aging the chocolate.

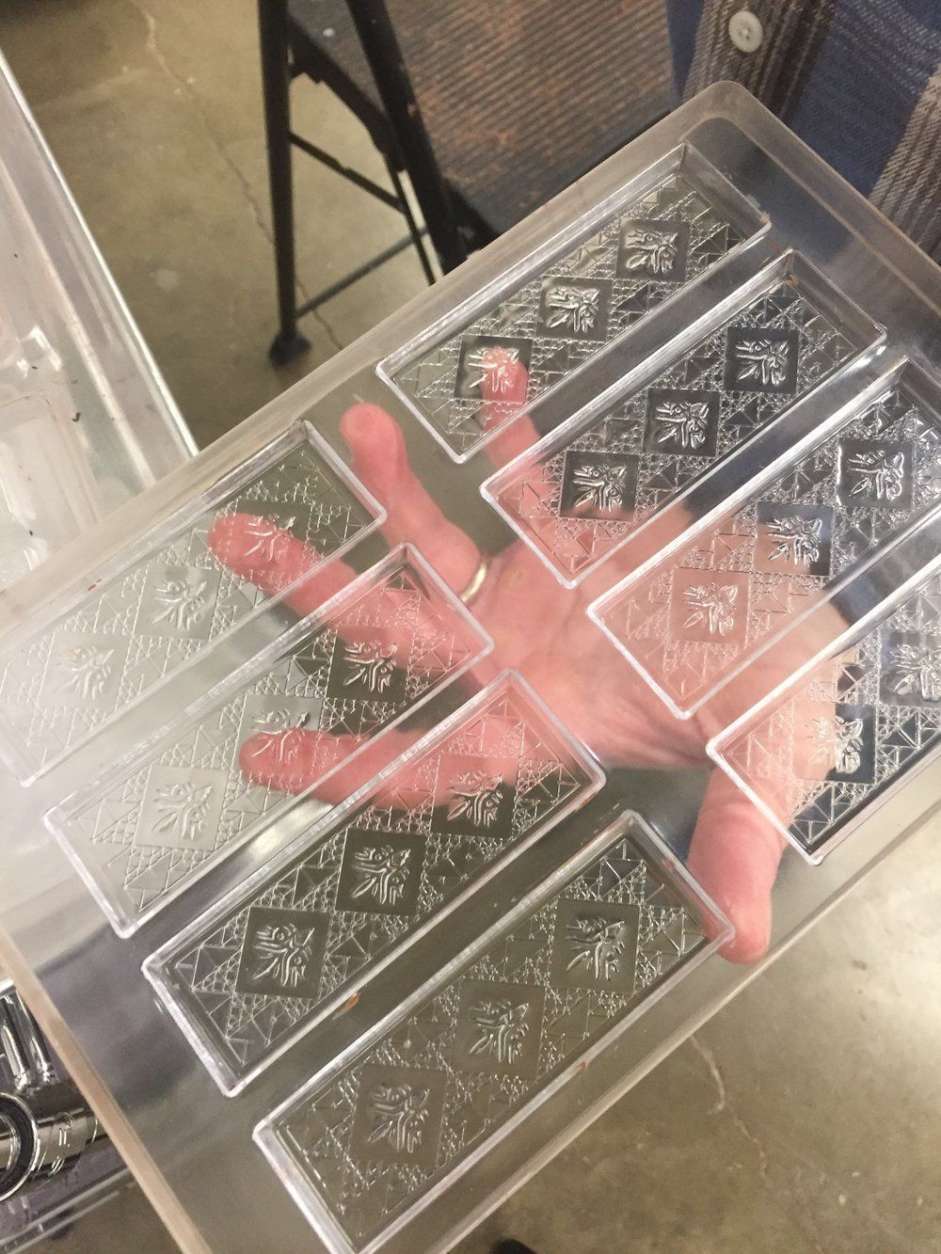

Tempering: A machine puts the chocolate in the right crystal structure so that it becomes shiny, and dries the correct way, and mixes each individual ingredient consistently throughout.

Chocolate poured into molds: These polycarbonate molds are made for the express purpose of creating craft chocolate bars. Once the chocolate is poured into these molds, the molds are lightly vibrated to release any remaining air bubbles before the chocolate is sent through one of its final stages: the drying stage.

Drying: The chocolate molds take about 20 minutes to pass through the conveyor belt. It is refrigerated and dehumidified to make sure the chocolate is dry and tempered before packaging.

Packaging: The final stage of the chocolate process is the physical packaging of the chocolate, which is done 100 percent by hand in the Harper Macaw facility.

For owners Sarah and Colin, maintaining a high-quality product, achieving impact on the conservation side, and promoting higher-quality cocoa production is more important than increasing production, and thus profit.

Harper Macaw’s main chocolate lines fall within three categories:

Rainforest Origin: A plain chocolate that showcases the cocoa beans sourced from three farms in Brazil. They offer this line individually in two sizes of bars, or gift sets of five bars, one big and one small.

Seasonal Collection: A recently introduced collection that features Fall Spice, Winter’s Cheer and a new spring seasonal.

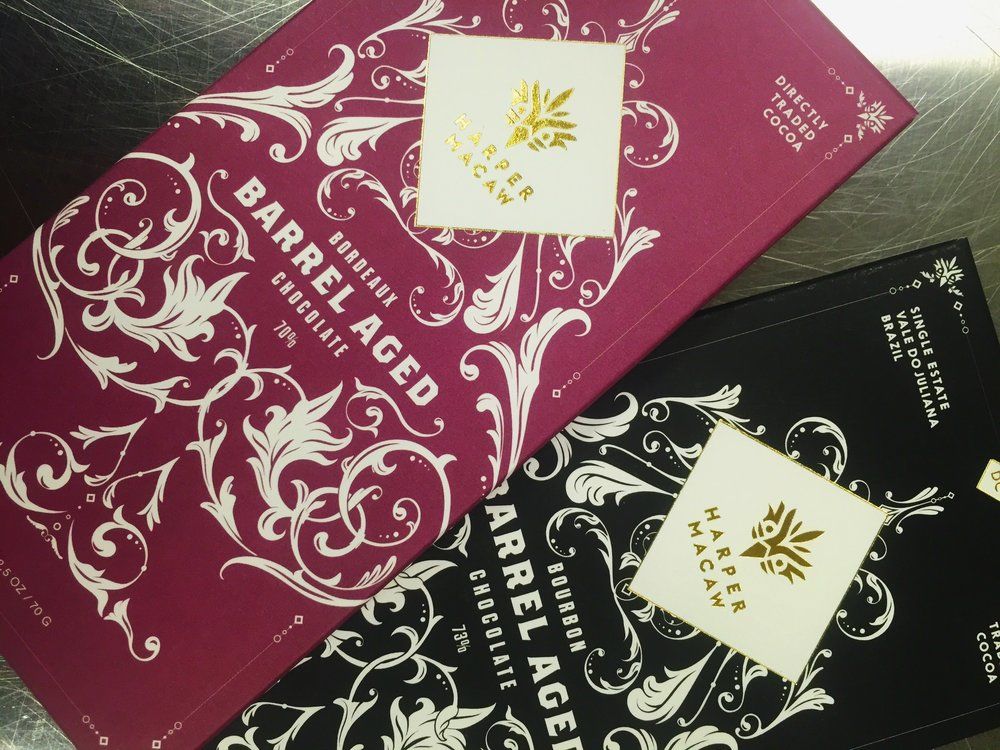

Barrel Aged Collection: Chocolate made from cocoa beans, aged in various types of freshly emptied oak barrels, used to age wine and spirits. These flavor profiles are enhanced by a unique oaky aroma that hits the nose and the tongue at different times, with different notes, depending on the aging process and American or French oak barrels in which they’re stored.

Harper Macaw is constantly innovating and experimenting to try unique flavor profiles. In an experiment with D.C.’s One Eight Distilling, they took an empty bourbon barrel, filled it with 200 pounds of cocoa nibs and aged it for six months. The result was a chocolate with subtle butter-vanilla notes that left a pungent oak-smokiness in its wake. And based on the popularity of the bourbon chocolate, Colin and Sarah decided to try their own spin on the world famous Bordeaux wine, except with — you guessed it — their craft chocolate.

With a Boudreaux-style French oak barrel from Virginia’s Early Mountain Vineyard, the chocolate makers combined a rich wine profile with their specialty dark chocolate, and voilà: an instant favorite. Most recently, their curiosity led them to rye whiskey.

Harpers Macaw has also done reverse collaborations, including a milk chocolate stout with DC Brau, a complement to four other collaboration brews that celebrated the brewery’s fifth birthday.

And just in time for Valentine’s Day, they’re launching a raspberry cheesecake chocolate bar with hints of dried raspberry and fresh crumbled graham crackers. The bar is available online or in stores at the following locations: Harper Macaw Factory Store, Harper Macaw Chocolate Boutique Pop-up at The Wharf DC, Glen’s Garden Market Dupont, Glen’s Garden Market Shaw, Shop Made in DC and Steadfast Supply Co.

This Valentine’s Day, you can help restore Brazilian rainforests, support local artisans and give your significant other something they’ll love — all in one package.

Read more from Elly on Facebook, subscribe on her blog at ByEllyJane.com and on Instagram.