WASHINGTON – People notice when they hear a claims of “world’s best screw.”

A startup company believes it can live up to the assertion, with an innovative product that is arousing considerable interest, not limited to prurient curiosity.

The invention? Something better than the current, and often infuriating, hardware screw.

“There hasn’t really been much advancement in this industry since the Phillips screw,” says Ron Elmore, director of marketing with Outlaw Fasteners.

When it goes on sale in the next few months, Elmore says the “World’s best deck screw” won’t strip, is less likely to be dropped, and will eliminate the need to change drill bits depending on the size of the screw.

Henry F. Phillips created the design for the Phillips screw drive and screw in 1935. The Phillips screw is characterized by the crosshead design, which resembles a plus sign.

The Phillips screw joined the earlier slotted screw, with its single slot in the screw’s head.

“The Phillips screw was designed to strip,” says Elmore.

At the time electric drills didn’t have clutches, which limit the amount of torque that will pass through to the bit.

To compensate, the Phillips screw and screw drive were designed to “cam out” – or have the screwdriver slip from the screw head – once the screw was in place.

The process often disfigures the crosshead design, resulting in miniscule metal shavings.

The problem comes when trying to remove the Phillips screw, says Elmore.

“Since it was virtually stripped going in, it becomes extremely difficult to reverse out.”

A new, better way to screw?

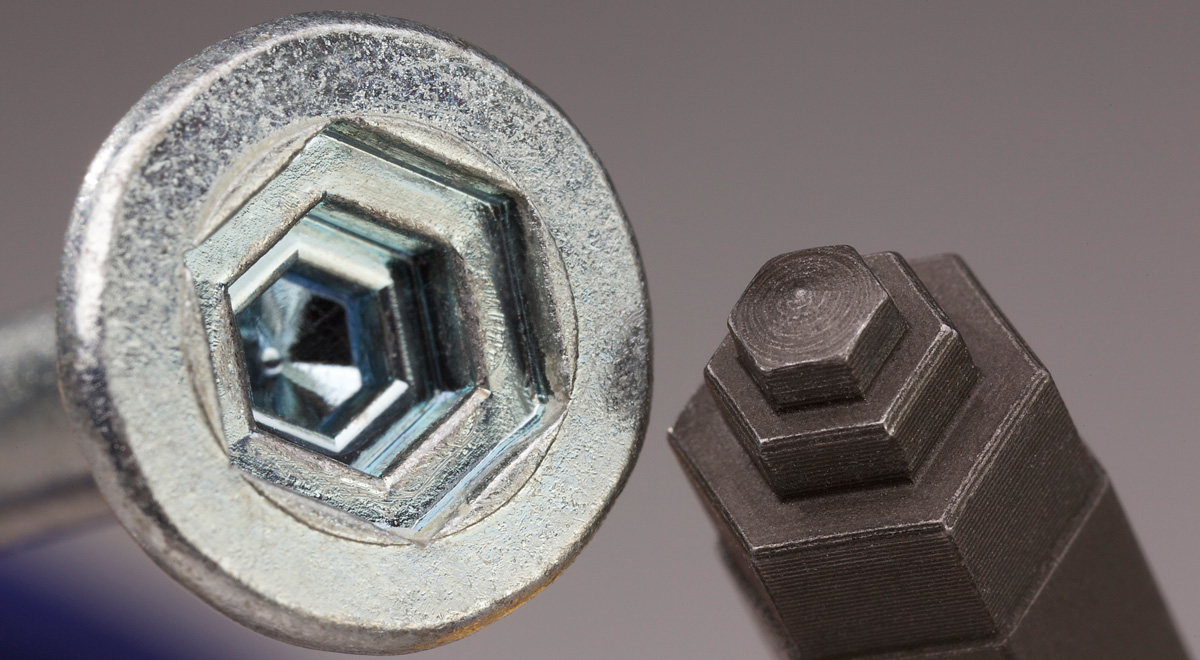

What makes “the world’s best deck screw” different is the number of contact points, says Elmore.

“The Phillips is limited by its points of contact, which is 4,” says Elmore. “Ours has 18.”

“The 18 points of contact are created by the drive head of multiple tiers,” says Elmore. “The hexagonal heads with three different tiers give you the 18.”

To the eye, the new screw more closely resembles an Allen screw.

Unlike an Allen screw, which has one depth, the Outlaw product has three levels.

While an Allen screw requires finding the appropriately-sized Allen wrench to turn it, Elmore says each box of screws will be shipped with a UniGrip bit, which will eventually work with all the different length fasteners the company develops.

“From a very small quarter-of-an-inch screw through an 8-inch screw, it’s the same drive system. It’s the same bit at the end of your drill,” says Elmore.

The design allows the screw to remain attached to the drill bit, without the use of magnets, enabling the user to hold the electric drill with one hand.