This video is no longer available.

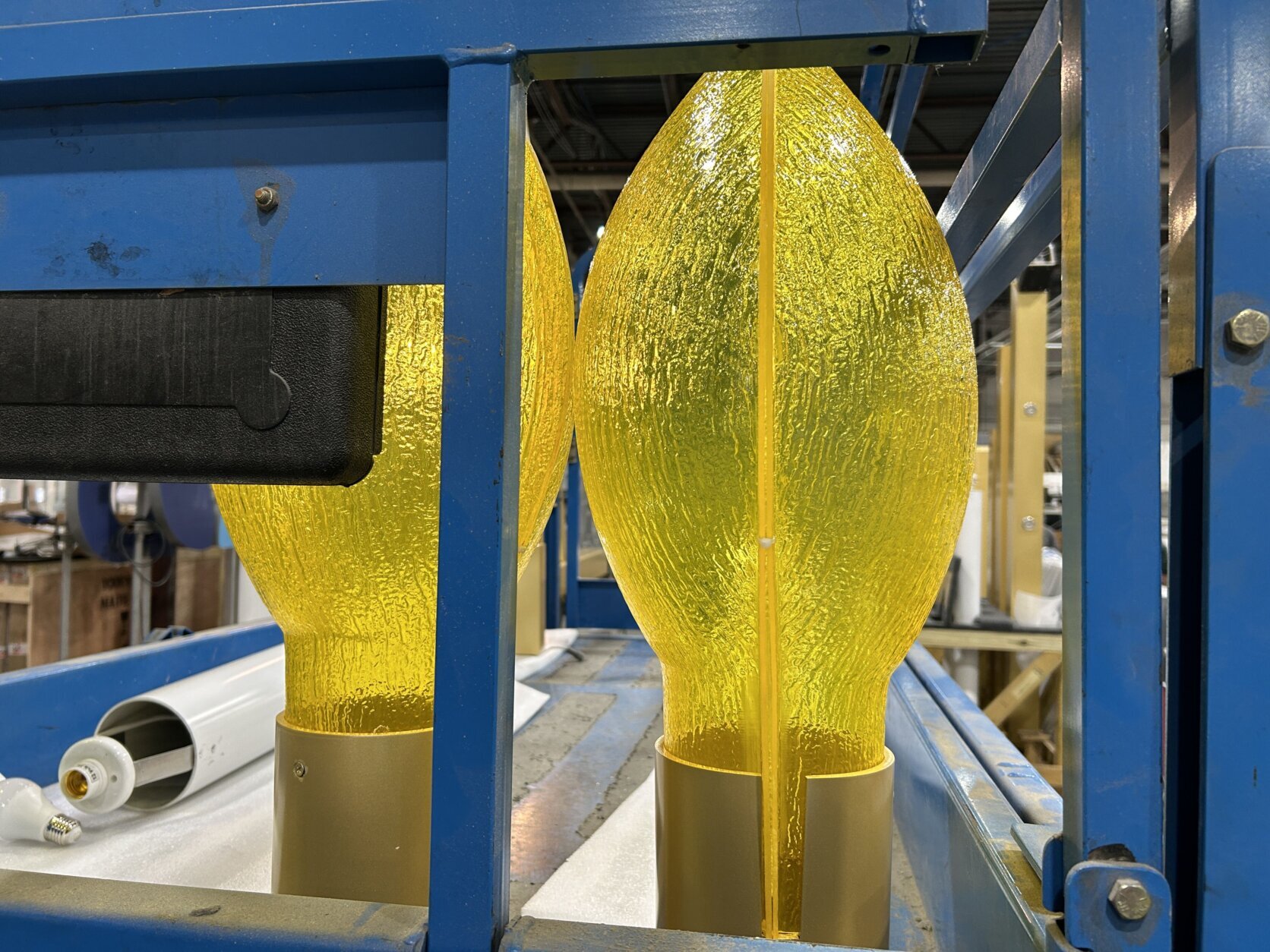

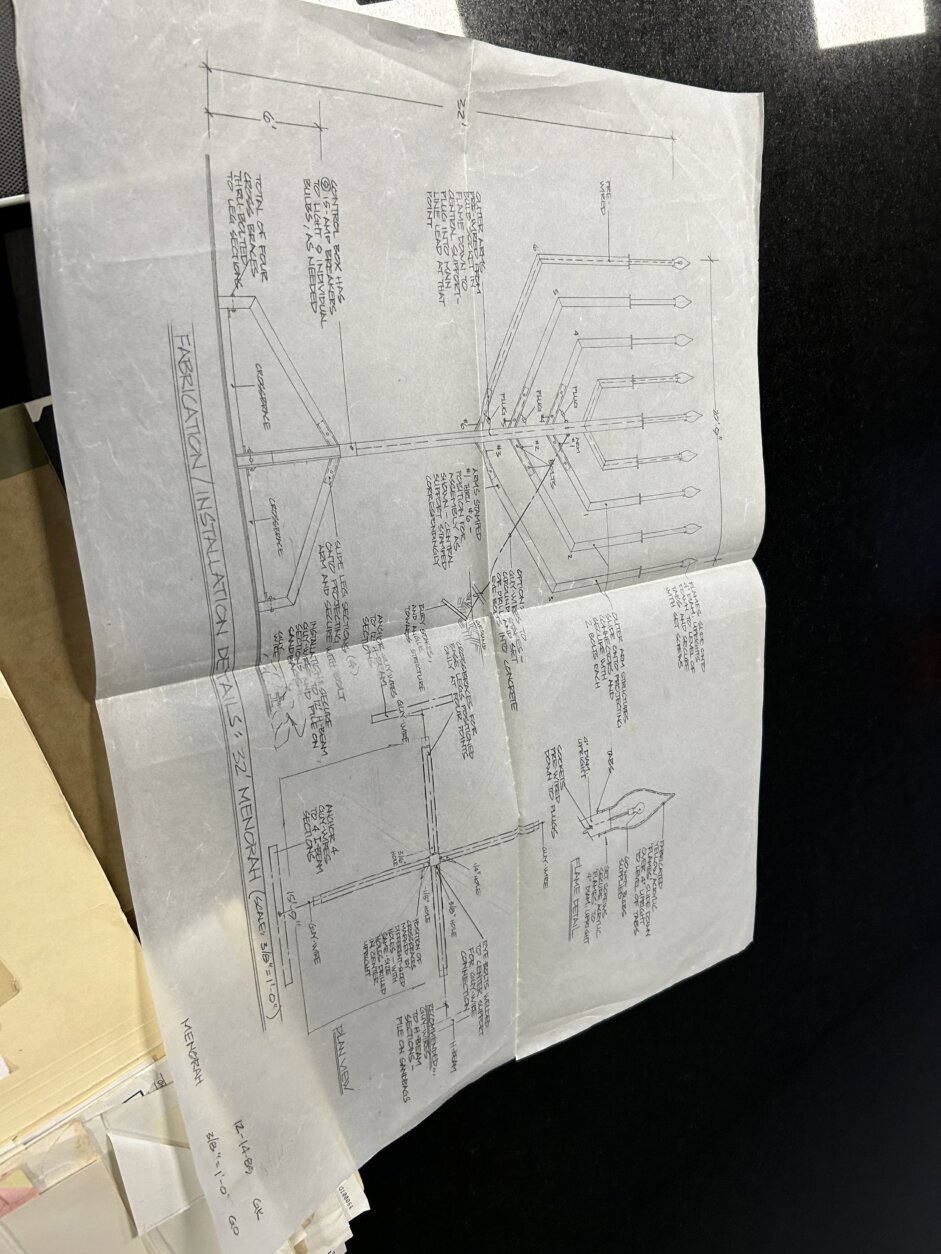

In the middle of Art Display Co.’s large warehouse in Capitol Heights, Maryland, the National Menorah sits between a Hummer sign and signage for an Inova facility.The latest iteration comes in pieces, so it can be maneuvered more easily. It used to have light bulbs and 110 volt wiring, but now, the components are LED lights with low voltage.

Previous versions of the menorah took two or three days to get in and out of The Ellipse near the White House. But now, it takes few hours.

It’s made of recycled aluminum, and at about 30-feet tall, takes five trucks to transport from the Prince George’s County facility to downtown D.C.

Decades after Gunther Kilsheimer started the company, his son, and now grandchildren, are carrying on his legacy. He fled the Holocaust, painting shuffle boards on the crew deck to pay his fare to Brazil. He ended up in D.C. with his dad painting on windows, and started the business in 1947.

And despite working on projects for restaurants, hospitals and other businesses, he remained excited about his role in crafting the National Menorah, which is scheduled to be lit up for the first night of Hanukkah this year on Christmas Day.

“Coming from Germany during the war and everything, and being able to put up the menorah meant a lot to him,” his son, Douglas Kilsheimer, said. “He practically did it for nothing at first, and it was just the proud fact of being able to do it and to have it across the street from the White House.”

Gunther’s role started when a local rabbi called and asked if he could build a menorah. He wanted to construct the largest menorah in the United States, and didn’t hesitate to say yes.

The first menorah he built was made out of steel and was very heavy. Then, there was a second generation version, which was aluminum but similarly heavy.

Now, as it has evolved, the company’s on its third generation of crews installing the menorah.

The menorah, grandson Brandon Kilsheimer said, “reminds me of when my grandfather started it, and how my father evolved it to what it is today.” He’s now the company’s vice president and treasurer, and his sister, Casey, is the president.

The siblings grew up attending holiday parties in the warehouse and getting in trouble for playing with the forklifts, helping prepare them for those roles.

“Until the day my grandfather died, he had his fingers in it. He was passionate about it,” Casey Kilsheimer said. “My dad is passionate about it. We’re here, and all these people here are passionate about it. It hits home.”

While the company has helped craft various large menorahs, it usually produces interior, exterior and business signs. It also works on specialty projects, for things like the butterfly house at the Smithsonian National Museum of Natural History.

“If it’s a sign, we make it,” Casey Kilsheimer.

The group has a team of about 100 employees, ranging from designers and project managers to sales representatives and installation crews.

Depending on the request, sometimes making the sign can take weeks, “so that it’s something that we’re proud of to put on your building and that you’re proud to show off. It’s not just a quick turnaround type of situation,” Casey Kilsheimer said.

And the goal is to create products that are made “like it’s something that your mother made, your grandmother made,” Brandon Kilsheimer added.

Get breaking news and daily headlines delivered to your email inbox by signing up here.

© 2024 WTOP. All Rights Reserved. This website is not intended for users located within the European Economic Area.